When you have successfully completed this section, you will have mastered the following:

Basics of Lighting Devices

It’s important to understand what to look for in vehicle lighting when choosing the correct product for a specific application.

Lenses

Take lenses for example. Lenses are typically offered in both acrylic and polycarbonate materials.

Acrylic lenses are an economical alternative where the service environment calls for a general duty material. They provide better than average performance in many situations.

For a service environment that calls for a tough alternative to acrylic, polycarbonate offers a cost effective material choice. Polycarbonate is more durable and more resistant to breakage.

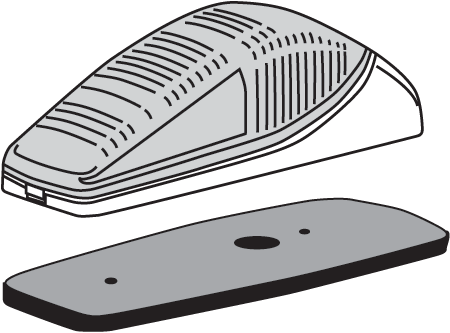

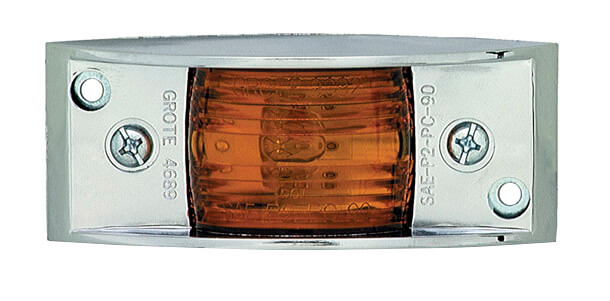

OEM-Style Chrome-Finish Marker Lamp

Bases

Bases are another primary and necessary component. They provide the foundation of the light. They also hold the socket for the bulb. Typically, the base contains the attachment points for the device.

Normal duty bases of ABS plastic provide an economical approach. They are available for a large number of styles and applications.

Alongwith ABS, Grote offers Duramold®, a tough, high performance material specially compounded for tough duty applications. It stands up to weather and harsh handling to provide a cost effective, long life product.

Some bases are available in metal. Among other things, a metal base provides extra durability for applications that must function in harsh environments. For example, die-cast metal side marker lights have bases that extend beyond the lens to help protect it from accidental impact with branches, structures or other abrasive contact. Metal bases and bezels are also used to add a decorative touch to vehicles as well as serving as functional parts.

Some bases are molded from tough plastics, but have the appearance of metal. They employ the same molding techniques used on other bases but also have a “chrome” effect applied, which adds a cost effective, decorative effect.

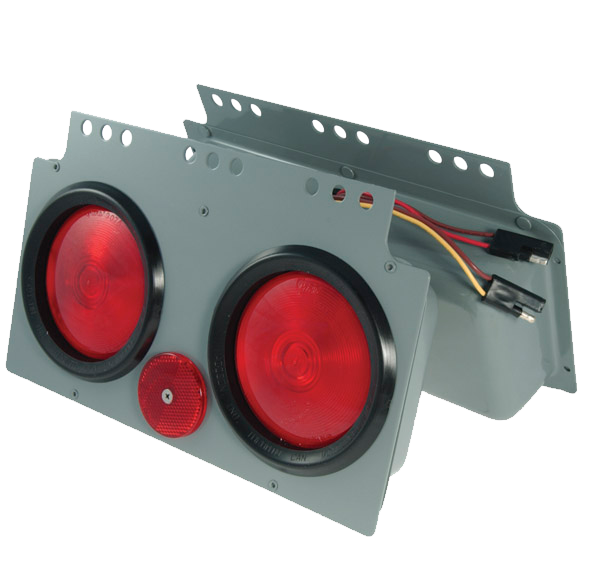

Other types of bases are used to support multiple lights. For example, bars are used for the top rear marker lamp clusters on semi-trailers. Installation is much more efficient compared to installing individual lights. Bars come in a variety of materials including tough plastics, enameled metal and extruded aluminum.

Incandescent vs. LED

Incandescent Tail Light

LED Tail Light

The lighting devices used on trailers fall into two categories, incandescent and LED. Incandescents are available in many sizes and varieties and are relatively inexpensive. However, their service life is comparatively short and they are very susceptible to vibration.

LEDs (light emitting diodes) on the other hand are economical since they last longer. They are less affected by vibration and generate less heat. And they’re efficient and offer superior light output.

Another distinction to be aware of is that not all vehicle lighting devices have “field replaceable bulbs.” In other words, not all devices have bulbs that can be changed when they fail. The ones that can’t are referred to as “factory sealed.” When sealed units fail, the entire unit has to be removed and replaced.

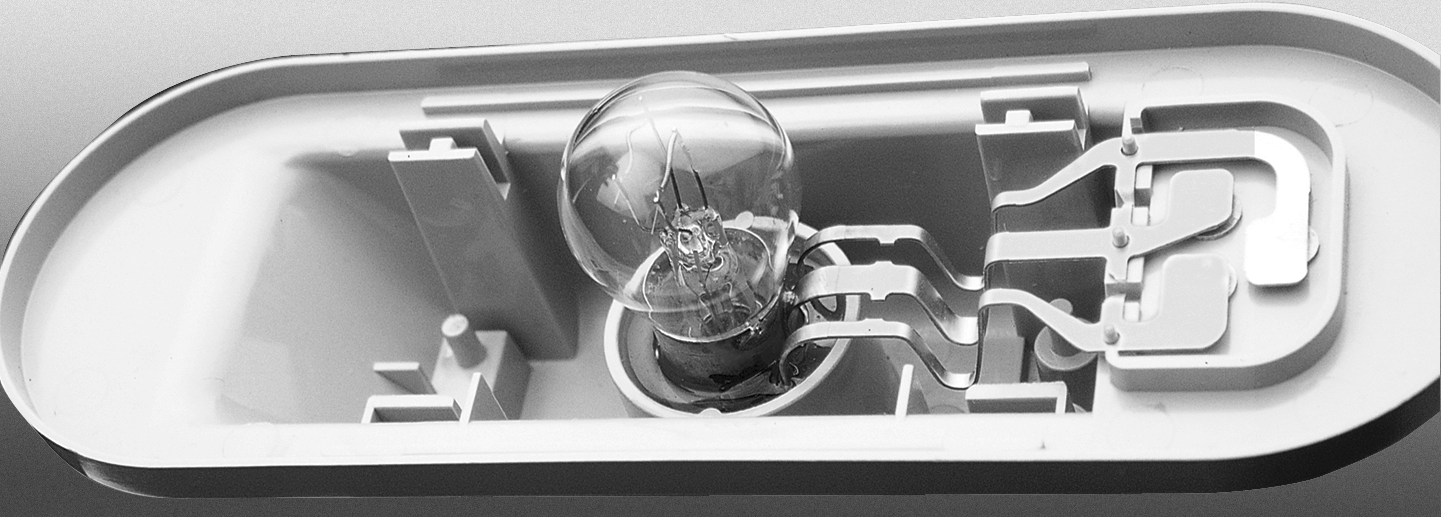

In this fixture, the lamp socket is filled with a soft gel material that dampens vibration and helps protect the contact points from moisture and corrosion.

Certain lights are constructed with an advanced development called the Torsion Mount II®, a unique design that suspends the bulb to protect it from vibration. With it, there are no wires inside the shell of the device. Instead, a brass assembly conducts the electrical current to the bulb and acts as a cradle for it.

Some of the newer designs use Gel-Mount® technology. Gel-Mount also uses a brass assembly to conduct the current. But the bulb is held in place by a unique gel material that dampens vibration while protecting the contact points from moisture and corrosion.

Overview of common lighting devices & applications

There are several general categories of devices and applications that make up the majority of lighting products sold for use on vehicles. For example, let’s consider truck trailers.

This clearance/marker lamp features a metal lens guard to protect the lens from damage.

Clearance and Marker Lamps

Side markers are required to be on the side of the trailer at the front and rear. Clearance lamps are required on the rear of the trailer. There are a minimum of two red clearance lamps and two red rear side markers required. Also required are a minimum of two yellow front side markers. Trailers over 30 feet, require a minimum of two additional mid-mounted side markers that are yellow. See the FMVSS-108 chart for specific applications.

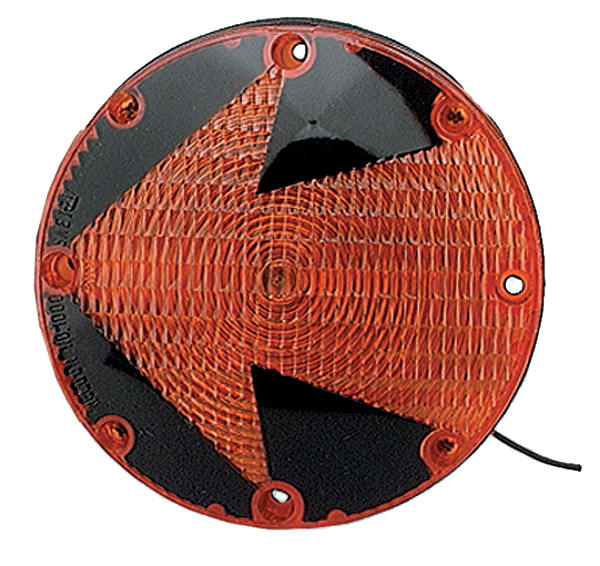

Stop, Tail and Turn Lamps

Another major category is the stop, tail and turn lamp group. Taillights are used on the rear to indicate the location of the vehicle, especially after dark. Stoplights are used to indicate that the vehicle is slowing or stopping. Turn lights warn other drivers that a vehicle is about turn or is in the process of turning. They come in red and yellow (amber). Tail and stop lamps must be red while turn lamps may be red or yellow according to FMVSS-108.

Stop/tail/turn lights come in modular units, like the one shown above, and as separate units.

Special purpose lights come in many forms. This turn signal is designed for use on a school bus.

There are numerous shapes and sizes in this category and they are chosen depending upon the size and type of the vehicle. They can be either surface mounted or recessed. At times, clusters of lights will be mounted in a special bolt-on metal plate. Or they may be a style that’s mounted on the fender of a truck using a bracket. Other variations include devices with built-in license plate lights, back-up lights and special units with large arrows for use on school buses. Use of stop, tail and turn lamps is required and is part of the information in the FMVSS-108 chart.

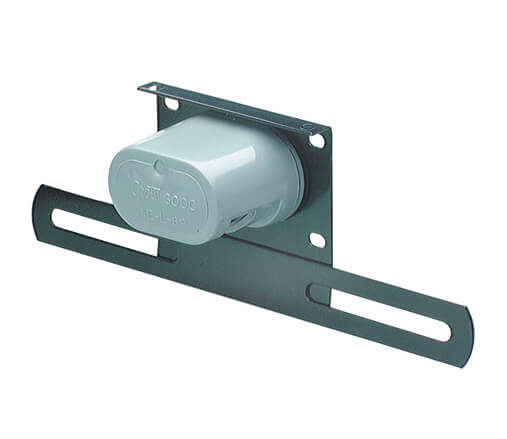

This license plate light includes a mounting bracket for the license plate.

License Plate Lights and Utility Lights

License plate lights always have white lights and clear lenses. License plate lamps come in a variety of shapes and sizes, some of which have a built-in bracket to hold the license plate. See the FMVSS chart for specifics on the use of license plate lighting.

Utility lighting also takes many forms. Grote supplies devices for surface-mount and recessed back-up lighting, trailer dome light applications and other applications where light is required for hooking up trailers, loading and unloading, repairs or a myriad of non-driving situations.

Forward Lighting

These quartz halogen lights can be used as driving lights or fog lights.

Another important category is forward lighting. It refers to the lights that illuminate the road ahead. Primarily, these are either round or rectangular and white (clear) or yellow (amber) in color. The category of forward lighting includes headlamps, driving lights and fog lights such as the Grote Per– Lux®. This category also includes snowplow and off-road lights and specially designed work lights for farm tractors.

Specialty Lighting

Specialty lighting includes emergency and warning devices. They come in a variety of colors including red, yellow (amber), blue and white.

These lights are seen on emergency vehicles of all types: fire vehicles, police vehicles and wreckers, along with school buses and industrial lift trucks. Devices come in a number of shapes and sizes. They are available as part of a car-top light bar, as independent, round, rotating beacons and as teardrop style, magnetic based “Kojak” lights.

Reflectors

Acrylic reflectors come with bolt holes (as shown above) or adhesive backing.

Conspicuity tape is used to identify both the presence and size of a vehicle.

Reflectors are non-powered warning devices. They are red and yellow (amber) colored depending on the position they are placed at on the vehicle, red on the rear and yellow on the side. When placed on the side, they’re used to indicate the presence and length of the vehicle. When used on the rear, they indicate the vehicle’s width. Reflectors are attached in two primary ways, using screws on some designs and an instant-bond, long-lasting adhesive on others.

Special, reflective, “conspicuity” tape is used on many larger vehicles to indicate presence and size. The majority of the tape is used on large trailers. Conspicuity tape comes in red and silver and is used in strips of alternating colors.

Use of either reflectors or conspicuity tape must meet FMVSS-108 standards.

Circuits & connections

The electrical system of a vehicle at first may seem complicated. However, there are certain basics that carry over from one system to another. Consider for instance, the system used on trailers.

In it’s most basic form, a trailer light circuit consists of a few primary parts. First, a power source, in this case the truck tractor (power unit). A switch in the circuit controls the flow of electrical power so the light receives electrical energy when the operator chooses, although this is not required. The third component is the lamp. Fourth is the ground point. In this case, the ground uses a return wire

to the tractor. Another variation is to use the “one wire” system and attach the ground wire to the

>trailer frame. In that case, the trailer frame is used as part of the electrical system completes the circuit.

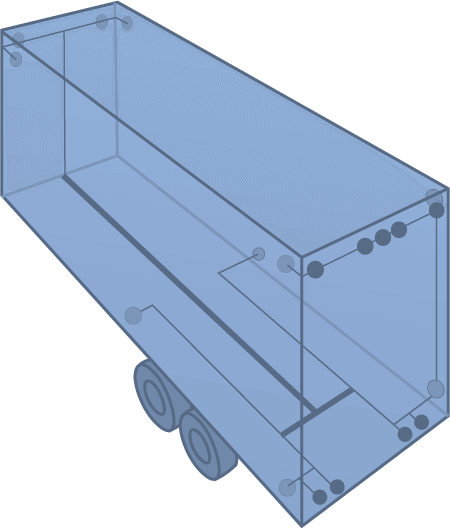

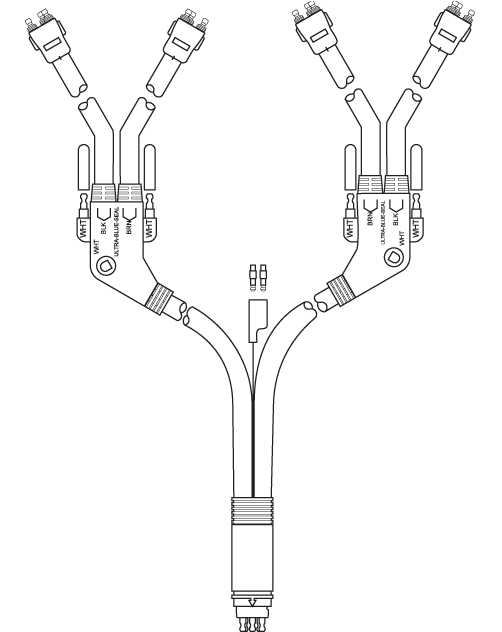

An important part of the lighting system of every truck is the wiring harness as represented by this trailer wiring schematic.

Another way of looking at the lighting circuit is to consider a trailer schematic. Each of the lighting elements of this system ties directly to a specific wire in the bundle of wires called the “wiring harness.” Those connections are color-coded to provide a standardized, consistent model both for the original installation and for repair and troubleshooting.

One of the major pieces is the main harness. It reaches from the front of the trailer to the rear. In the front, it plugs into the “nose box,” the device that provides a connection point for the seven wires of the trailer and matching wires of the tractor. It may accept connections from lighting devices in the front area.

In the rear, the main harness plugs into the “sill harness.” That consists of the wiring and fittings that provide the electrical connections from lighting devices, primarily located on the sides and rear of the trailer.

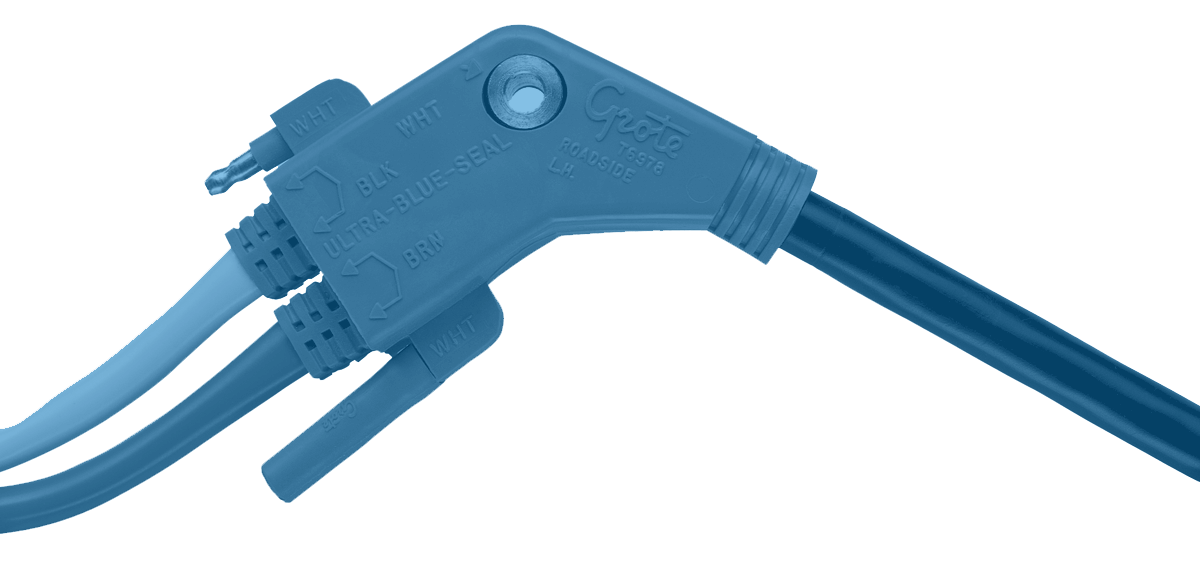

Pigtail Connections

Together, the two harnesses make up the backbone of the trailer wiring system. Connections are made in the UBS (Ultra Blue Seal) system by plugging a pigtail (the shortest of the connectors) into a light, then into a jumper, a longer cable that feeds into

a trailer wiring harness such as the UBS system. Both pigtails and jumpers are available to provide a custom connection for almost any set of circumstances and configuration.

Ultra Blue Seal (UBS) connectors are designed to protect wiring and connections against moisture, corrosion and vibration.

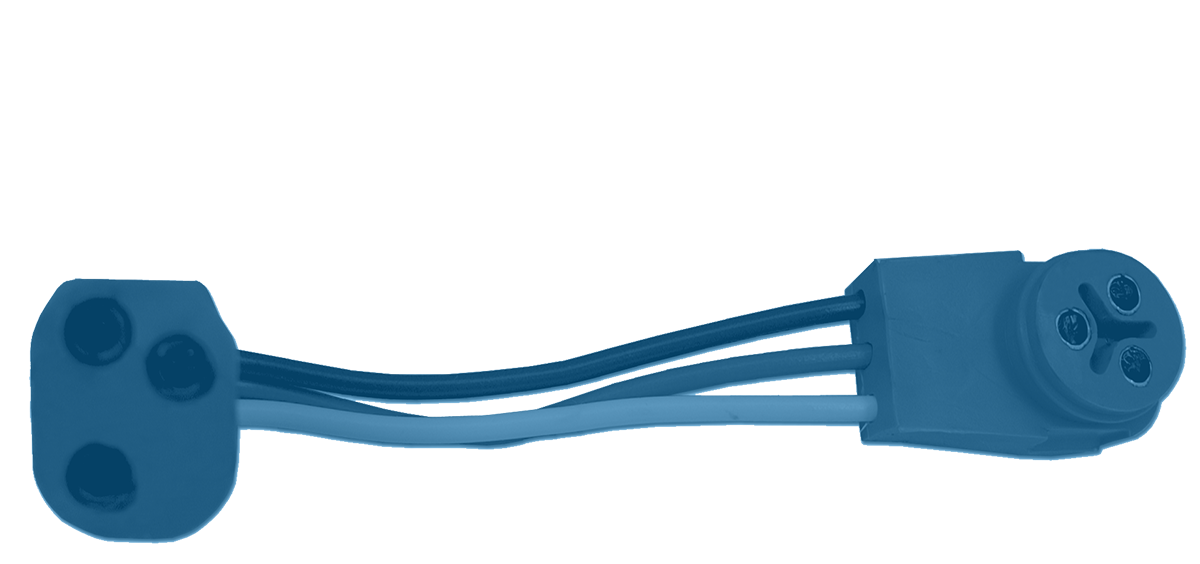

This pigtail connector is terminated at both ends with a connector.

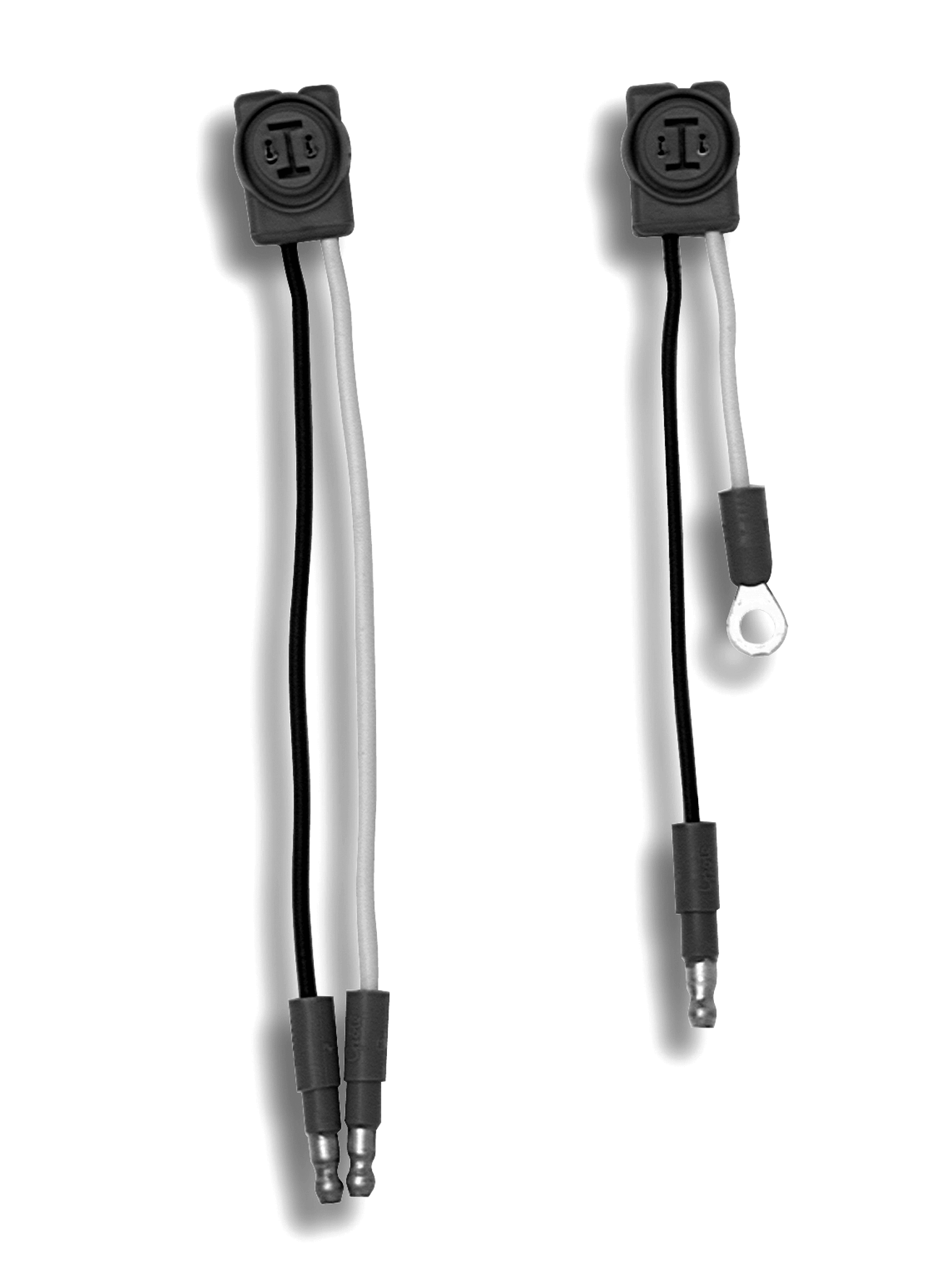

Examples of pigtail connectors with a variety of wire terminations.

Thin-Line pigtails are specially designed to fit under new LEDs.

Pigtails are specially designed with a variety of “boot” (connector) configurations, wire lengths and terminations to fit most applications. Probably the most basic difference to be aware of is the distinction between male and female connection. The easy way to determine which connector to use is to check the lighting device to see whether

the terminals on the light protrude or are recessed. Protruding (male) terminals require a female connector. Recessed (female) terminals require a male connector.

Only Grote pigtails feature the new “Double Seal” version. The Double Seal effect is the result of a custom engineered, molded-in circular slot in the boot. That slot matches a corresponding ring molded into the base of the lighting device. When joined together, the Double Seal pigtail grips the ring on both sides for a secure, protective seal when compared to ordinary seals.

Another Double Seal advantage is the center grease slot. Once assembled, this slot provides an area for the grease to escape to when grease is

applied to the lamp terminal during normal maintemance. Without it, the pressure from the grease could cause a bad connection between the pigtail and the lamp.

Terminations on the pigtails take one of three basic forms. One is the blunt cut, a straight cut off with the insulation stripped and ready for a terminal to be attached. Another is the ring connector, primarily used to attach to a ground point. Third is a bullet connector which plugs into the power source. Another use for a lead with a bullet connector is to connect to a ground source in cases

where the truck’s metal frame is not being used for that purpose.

Pigtail assemblies come in standard types as well as a unique new development, the Thin-Line. The compact design makes it the only connector that fits under the new LEDs. In addition, Thin-Line pigtails have a patented double-seal design and grease slots for long lasting protection.

Since moisture has such a harmful effect on wiring; the UBS provides features and benefits not found in other approaches. First, it is a fully modular system. All of the elements of the system are designed and engineered to work together. UBS works with sealed or field resealable devices. It is a true plug-together system requiring minimal tools and splices. UBS is the first modular sealed system. Repairs are simple to make. For example, if the sill harness is damaged it can be un-plugged from the main harness and replaced.

The new UBS harness system is a true plug-together system that provides a lowmaintenance, weatherproof seal.

UBS connectors are designed to provide a durable, weatherproof seal quickly and easily. They help to prevent corrosion and exclude contamination that can shorten service life. UBS requires low maintenance. Road failure and breakdowns are minimized.

New on the market is the UBS Factory Sealed Lamp System. It uses all factory-sealed lamps with hermetically sealed, unitized lens and housing design. The devices are designed and engineered to remain tight for the life of the lamp. All of

the lamps are road proven to seal out water, salt and other contaminants and are not effected by extremes of heat and cold.

This UBS system includes task matched wiring. All components needed for completing the trailer are included in the kit. This unique advance in trailer wiring assures the optimal system and provides users with a time saving ordering process.

Use the self assessment below to gauge your understanding of this section. Place your answer in the box and then check your answer by clicking on the "show answer" link.

Or, you can skip the assessment.

Instructions:

Read the question.

Place your answer in the box.

Example:

True or False:

You should read the questions and then type your answer into the box.

show answer

True!

Begin:

1. True or False: For severe service or where vandalism is a problem, polycarbonate lenses are recommended.

show answer

True

2. Which of the following is not a function of a base?

show answer

d) Connecting a device to the wiring harness

3. True or False: Metal bases are not used because they cause short circuits

show answer

False

4. True or False: Some molded plastic bases have a chrome finish.

show answer

True

5. A typical trailer light bar is used with:

show answer

a) Top rear identification lamps

6. True or False: Light bars are available in plastic.

show answer

True

7. Which of the following is not true about incandescent bulbs? They are______.

show answer

b) Very resistant to vibration

8. True or False: Factory-sealed lights can be opened to change bulbs if they are carefully resealed.

show answer

False

9. Gel-Mount technology is used to:

show answer

d) All of the above

10. True or False: Clearance/marker lamps are used to illuminate obstacles when maneuvering a truck in tight quarters at night.

show answer

False

11. True or False: Clearance lamps are required on the rear of the trailer.

show answer

True

12. True or False: Trailer stop lamps can be red or yellow.

show answer

False

13. Stop, turn and tail lamps may ______

show answer

d) All of the above

14. True or False: License plate lights must have clear lenses.

show answer

True

15. True or False: It’s illegal to have a license plate holder attached to a light.

show answer

False

16. True or False: Forward lighting refers to the front most clearance and marker lights on a trailer.

show answer

False

17. Fog lamps, driving lights, snowplow lights and off-road lights are best referred to as:

show answer

c) Forward lighting

18. True or False: Reflectors are non-powered warning devices.

show answer

True

19. Which of the following is true about reflectors?

show answer

d) All of the above

20. True or False: Conspicuity tape is used to indicate presence and size of a trailer.

show answer

True

21. The only conspicuity tape allowed to be used on trailers comes in which of these color combinations:

show answer

c) Red & Silver

22. In a simplified trailer lighting circuit, which element is not required?

show answer

c) Switch

23. A bundle of wires in a trailer lighting system is called a:

show answer

a) Harness

24. True or False: The nose box makes it possible to connect truck tractor wiring with a trailer wiring harness using a single connection.

show answer

b) True

25. The sill harness is typically used to plug lights into:

show answer

b) The rear of the trailer

26. True or False: A pigtail is an extra-long wire that connects a jumper and a wiring harness.

show answer

False

27. True or False: In determining the right style of connector, a protruding terminal on a lighting device means choosing a female style connector.

show answer

True

28. A “Double Seal” pigtail refers to:

show answer

b) A slot and ring design that provides an inner and outer seal

29. True or False: Pigtails primarily use three terminations: bullet connectors, blunt cut and ring connectors.

show answer

True

30. True or False: Replacing a damaged sill harness requires little more than unplugging it from the main harness and lights and replacing it.

show answer

True